Data Acquisition and Control Systems: Precision, Speed, and Reliability

Buy NI Data Acquisition (DAQ) and Control Systems

Ni data acquisition and control systems provide engineers and researchers with high-performance tools for measuring, monitoring, and automating physical processes. These systems are trusted worldwide for their accuracy, reliability, and scalability in applications ranging from industrial automation to scientific research and product validation. Built by National Instruments, ni data acquisition and control systems deliver precise data collection, real-time processing, and seamless integration with LabVIEW, CompactDAQ, CompactRIO, and other NI hardware platforms.

Why Choose NI Data Acquisition and Control Systems

Reliable Performance in Industrial and Harsh Environments

Ni data acquisition and control systems are designed for durability and consistency. They operate flawlessly in extreme temperatures, high vibration, and challenging environmental conditions, ensuring uptime in mission-critical applications such as aerospace, automotive testing, and process control.

High-Speed and High-Accuracy Data Collection

Each system offers high-resolution sampling and low-noise signal acquisition for precise measurements of voltage, current, temperature, strain, and other physical parameters. Engineers use ni data acquisition and control systems to capture real-time data and perform in-depth analysis across multiple channels and sensors.

Real-Time Processing and Control

These systems combine data acquisition with embedded control, enabling immediate system response for automation, predictive maintenance, and advanced testing. The ability to process data in real time allows for dynamic adjustments and continuous monitoring in industrial and laboratory settings.

Modular and Scalable Architecture

Ni data acquisition and control systems support modular expansion, allowing users to configure their setups based on application needs. Whether you require a few analog input channels or hundreds of mixed-signal measurements, you can easily scale with additional modules and chassis without redesigning your entire system.

Seamless Integration with NI Software

Designed for full compatibility with LabVIEW, TestStand, and FlexLogger, these systems streamline data analysis, automation, and visualization. Engineers can control complex test setups, record large datasets, and perform automated reporting all within one unified software environment.

Key Benefits of NI Data Acquisition and Control Systems

- Reliable operation in industrial and laboratory environments

- High-speed, high-accuracy data measurement and recording

- Real-time data processing and control for automation

- Scalable modular architecture for easy expansion

- Full software integration for efficient workflow management

Applications of NI Data Acquisition and Control Systems

- Industrial Automation and Process Monitoring: Real-time data from sensors, actuators, and machinery for optimized production control.

- Test and Measurement Systems: Accurate signals for R&D, prototype validation, and regulatory compliance testing.

- Automotive and Aerospace Engineering: Monitoring engine performance, vibration, and avionics system behavior.

- Energy and Power Systems: Tracking grid stability, renewable energy output, and power quality metrics.

- Medical and Biomedical Research: Capturing physiological and instrumentation data for analysis and diagnostics.

NI Data Acquisition Platforms

- NI CompactDAQ: Modular, USB- and Ethernet-based systems for flexible data collection and logging.

- NI CompactRIO: Real-time embedded systems with FPGA-based processing for advanced control applications.

- NI PXI: High-performance platform for large-scale automated testing and high-speed signal acquisition.

Frequently Asked Questions About Data Acquisition (DAQ) Systems

What is Data Acquisition (DAQ)?

Data acquisition systems measure and monitor physical or electrical phenomena such as temperature, voltage, or current. They are used to verify designs, control processes, and analyze performance using dedicated devices and software for measurement and automation.

What Comprises a DAQ System?

A DAQ system includes both hardware and software that sample physical parameters like voltage, current, and temperature through sensors or transducers. Many modern ni data acquisition and control systems also feature embedded controllers for real-time processing and system control.

How Is a DAQ System Utilized?

Typical uses include product characterization, process monitoring, and automated testing in research labs or production environments. Engineers use DAQ systems to collect, process, and analyze data for validation and optimization.

What Types of Measurements Can a DAQ System Perform?

- Current — DC and AC

- Temperature — thermocouples, RTDs, and thermistors

- Resistance — 2-wire and 4-wire measurements

- Frequency and Period — signal timing and response metrics

- Voltage — DC and AC signals

- Digital Signals — monitoring input and output states

Advantages of Using NI Data Acquisition and Control Systems

- Flexible configuration for diverse measurement applications

- Industry-proven reliability with long-term support

- Compatibility with thousands of NI and third-party sensors

- Fast installation and easy integration with automation networks

- Comprehensive documentation and software libraries for rapid deployment

Comparison: NI Data Acquisition vs Traditional Measurement Systems

| Feature | NI Data Acquisition and Control Systems | Traditional Systems |

|---|---|---|

| Architecture | Modular, scalable, and software-integrated | Fixed, standalone devices |

| Data Speed | High-speed PCIe, USB, or Ethernet transfer | Limited bandwidth interfaces |

| Integration | Seamless with LabVIEW and TestStand | Manual synchronization required |

| Expandability | Plug-and-play modular expansion | Minimal or no upgrade capability |

| Automation Support | Real-time data processing and control | Offline analysis only |

Industries That Benefit from NI Systems

- Manufacturing and process automation

- Aerospace and defense engineering

- Automotive and transportation systems

- Energy production and smart grids

- Medical research and life sciences

Upgrade Your Testing and Automation

Ni data acquisition and control systems deliver the precision, flexibility, and scalability required for industrial, research, and test applications. For monitoring critical processes, automating testing workflows, or developing new technologies, these systems offer reliable, efficient, and high-performance solutions. Contact us today to learn more and order ni data acquisition and control systems tailored to your needs.

Categories

Sort By

-

USB-6009

Data Acquisition and Control Systems -

USB-6008 OEM

Data Acquisition and Control Systems -

USB-6008

Data Acquisition and Control Systems -

USB-6003 OEM

Data Acquisition and Control Systems -

USB-6003

Data Acquisition and Control Systems -

USB-6002 OEM

Data Acquisition and Control Systems -

USB-6002

Data Acquisition and Control Systems -

USB-6001 OEM

Data Acquisition and Control Systems -

USB-6001

Data Acquisition and Control Systems -

USB-6000

Data Acquisition and Control Systems -

USB-5681

Data Acquisition and Control Systems -

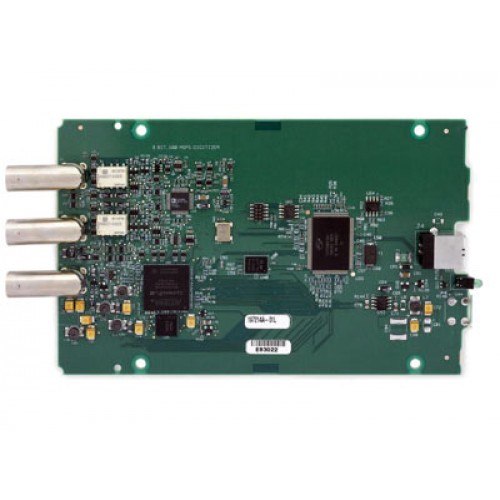

USB-5133 OEM

Data Acquisition and Control Systems