Li-Ion Battery Quality Control with an SMU Station

Published by: Sohoprolab Editorial Team | Date: July 8, 2025

Introduction

With the rise of electric vehicles, medical wearables, and portable electronics, Li-Ion battery testing has become critical in both R&D and mass production. Among the most accurate and flexible test tools available is the Source Measure Unit (SMU) — capable of both sourcing voltage/current and measuring response with precision at microamp and microvolt levels. In this article, we walk through how an SMU-based station enables automated, accurate, and traceable battery quality control from initial screening to end-of-line validation.

Why Use an SMU for Battery Testing?

SMUs combine four key capabilities in one instrument: sourcing voltage, sourcing current, measuring voltage, and measuring current. This makes them ideal for battery tests such as:

- Open-circuit voltage (OCV) verification

- IV sweep and dynamic resistance measurement

- Leakage and self-discharge detection

- Charge-discharge profiling

SMUs also support precise timing, sourcing under current compliance, and sweep generation — features essential when validating tight tolerance batteries used in high-reliability applications.

Typical SMU Station Architecture

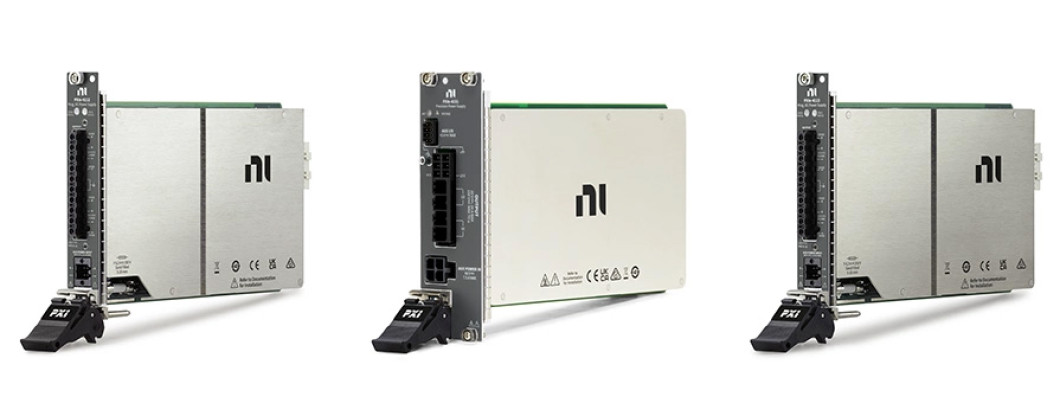

A typical battery test setup using PXI or benchtop SMUs includes:

- Programmable SMU (e.g., NI PXIe-4143): for cell-level testing

- Switching matrix: to connect multiple cells in sequence

- Temperature chamber or probe: for thermal behavior simulation

- Safety interlocks & cutoff relays: for overvoltage/current events

- Test software (e.g., LabVIEW or Python): for sequencing and data logging

For high-throughput setups, multiple SMUs can run in parallel in a PXI chassis with synchronized timing across channels.

See compatible modular hardware in our PXI Modules section.

Step-by-Step Battery QC Tests with an SMU

1. Open-Circuit Voltage Check (OCV)

Quickly identifies undercharged or dead cells. SMU performs a passive voltage read after stabilization time.

2. IV Characterization Sweep

Applies incremental voltage/current steps and measures corresponding current/voltage. Results used to extract internal resistance and non-linear behavior.

3. Leakage Current Test

At near-zero voltage bias, the SMU measures sub-μA leakage to identify insulation breakdown or separator defects — critical in medical battery QC.

4. Charge Profiling

Constant-current charging with periodic voltage logging (CC-CV behavior). Allows detection of weak chemistries or poor SOC tracking.

5. End-of-Line (EOL) Validation

Includes short test, polarity check, and residual capacity validation before packaging. SMUs can automate PASS/FAIL classification and barcode logging.

Key Advantages Over Power Supplies and DMMs

- High-resolution sourcing: Up to 100 fA / 100 nV sensitivity

- Integrated timing and sweeps: No external waveform generator required

- Four-quadrant operation: Enables sourcing and sinking power

- Compact modular form factor: PXI-based stations scale easily

Unlike traditional power supplies, SMUs support very low-leakage measurements and offer stable sourcing under high impedance loads.

FAQ: SMU Battery Testing

- Can I test multiple cells with one SMU?

- Yes, by using switching modules or relays — but parallel testing is faster with multi-channel SMUs like PXIe-4145.

- What current range is needed for Li-Ion cells?

- Typically 10 μA to 2 A, depending on cell size. SMUs with auto-ranging handle both trickle and fast charge levels.

- What safety measures should I implement?

- Use overcurrent clamps, thermal monitoring, and automatic cutoff circuits, especially for high-capacity packs.

Conclusion

SMU-based stations offer unmatched precision, flexibility, and automation for Li-Ion battery quality control. From R&D cell screening to production end-of-line validation, SMUs deliver insights that traditional tools simply can't. Explore advanced SMU test modules in our Electronic Test & Instrumentation section or build your modular system from the PXI Platform.