CompactRIO Controller vs. x86 Controller: Pros and Cons in Harsh Environments

Published by: Sohoprolab Editorial Team | Date: July 8, 2025

Introduction

Choosing between a CompactRIO (cRIO) controller and an x86-based controller depends heavily on the operating environment, control architecture, and long-term maintainability. In harsh environments where vibration, temperature, and EMI can affect performance, understanding the difference between rugged embedded systems and traditional PC-based architectures is essential.

What is a CompactRIO Controller?

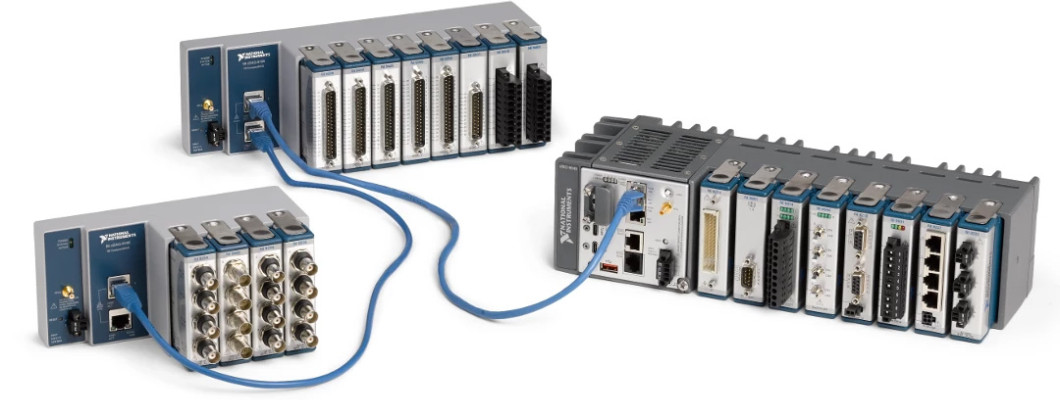

CompactRIO is a rugged, reconfigurable control system from NI that integrates real-time processors, FPGAs, and modular I/O. Designed to operate in extreme conditions, cRIO excels in deterministic control, hardware-timed acquisition, and high-reliability automation.

- Operating range: –40 °C to 70 °C

- Shock and vibration rated (up to 50g)

- Ideal for oil & gas, mining, transportation

What is an x86 Controller?

An x86 controller uses Intel or AMD processors with a general-purpose OS like Windows or Linux. These controllers offer high flexibility, processing power, and compatibility with commercial software stacks, but are generally less suited for mission-critical control in rugged environments unless specifically hardened.

- Broad software compatibility (LabVIEW, Python, ROS)

- Less deterministic timing without real-time extensions

- Limited environmental tolerance unless industrial-rated

Comparison Table: CompactRIO vs. x86 Controller

| Feature | CompactRIO | x86 Controller |

|---|---|---|

| Operating Temperature | –40 °C to 70 °C | Typically 0 °C to 50 °C |

| Shock/Vibration | Up to 50g shock, 5g vibration | Limited without ruggedization |

| Deterministic I/O | Yes, via FPGA and RTOS | No, unless using real-time kernel |

| Modularity | High – supports C Series modules | Varies – often fixed I/O |

| Ease of Integration | Tight with NI ecosystem | Broad but less deterministic |

Use Cases for CompactRIO

- Real-time vibration monitoring in mining machinery

- On-vehicle control systems in harsh environments

- High-speed hardware-timed data logging

Use Cases for x86 Controllers

- Industrial HMI systems with full graphical UIs

- Data processing and analytics at the edge

- General-purpose control and monitoring in clean factory floors

Frequently Asked Questions

- Is CompactRIO better than x86 for harsh environments?

- Yes, CompactRIO is purpose-built for shock, vibration, and temperature extremes.

- Can x86 platforms achieve deterministic performance?

- Only with real-time operating systems like NI Linux RT or Windows with RTX extensions.

- Which is better for long-term reliability?

- CompactRIO generally offers longer MTBF and better hardware resilience in critical environments.

Conclusion

Both CompactRIO and x86 controllers have advantages depending on use case and environment. In rugged, mission-critical settings, CompactRIO offers superior reliability and deterministic performance. For broader software flexibility and UI-rich systems, x86 remains a strong choice. Learn more about rugged modular platforms in our Compact FieldPoint section or explore distributed systems via CompactDAQ.