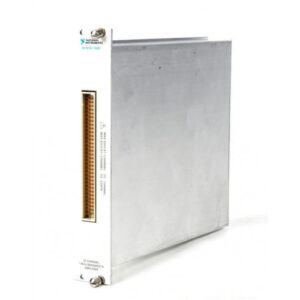

NI SCXI-2400 — Remote Communications Module

Long-tail friendly overview:

The NI SCXI-2400 is a serial communications module for the SCXI system that allows you to control an SCXI chassis via a PC using RS-232 or RS-485. Ideal for remote chassis control in modular data‐acquisition systems, it supports long‐distance connections and multi‐chassis networks by using the RS-485 port and configurable HDLC addressing. It integrates into any SCXI chassis slot, giving you flexibility to manage the chassis from a computer rather than relying solely on local controller modules.

Key features:

-

Supports RS-232 (9-pin D-sub) direct PC connection and RS-485 screw-terminal adapter for long-distance / multi-chassis setups.

-

Front-panel DIP switches let you set HDLC address (1-254) and baud rate (300 bps to 57.6 kbps and more).

-

Compatible with NI SCXI chassis such as SCXI-1000, SCXI-1000DC, SCXI-1001 etc.

-

Fits into an SCXI chassis slot, so it uses standard SCXI backplane signals.

-

Physical size: approx 3.0 × 17.2 × 20.3 cm (1.2 × 6.8 × 8.0 in) typical.

-

Legacy/Archived device: for older SCXI systems. Support information lists SCXI devices under legacy NI-DAQ and NI-DAQmx driver support.

Typical applications:

-

Remote monitoring/control of SCXI chassis that house analog input/output, strain/bridge, vibration modules within test rigs or lab instrumentation.

-

Multi-chassis setups where the chassis may be physically distant from the PC and connected via RS-485 network.

-

Retrofitting older SCXI systems where a serial control module is required to interface with modern computers or DAQ software.

Limitations & things to check:

-

It is a control/communications module — does not itself perform analog/digital I/O. You’ll still need the proper SCXI modules for measurement.

-

Since it’s legacy, check driver and OS compatibility (it may require legacy NI-DAQ rather than current NI-DAQmx).

-

If you’re using modern USB/Ethernet DAQ systems, there might be more convenient alternatives for remote chassis control.

-

Ensure cable length and network configuration rules for RS-232/RS-485 (e.g., termination, twisted-pair, 120Ω resistors for RS-485) are followed.

Basic technical specs (excerpt)

| Parameter | Specification |

|---|---|

| Connector – RS-232 | 9-pin male D-sub (AT pinout) |

| Max RS-232 cable length | ~2,500 pF capacitance (~100 ft typ) |

| RS-485 connector | 4-pin screw terminal on adapter board |

| Baud rate DIP settings | From 300 bps up to 57.6 kbps (various) |

| HDLC Address | Switches allow address 1-254 (0 & 255 reserved) |

| Physical dimensions | 3.0 × 17.2 × 20.3 cm (1.2 × 6.8 × 8.0 in) |

| Environment / compatibility | Works in any SCXI chassis slot; use proper configuration of chassis software & modules. |

| Parameter | Specification |

|---|---|

| Model | NI SCXI-2400, P/N varies by kit (verify on unit label) |

| Interfaces | RS-232 (9-pin D-sub); RS-485 (via 4-pin screw-terminal adapter) |

| Baud Rate | 300 bps to 57.6 kbps (selectable via DIP switch) |

| Addressing | HDLC address settable 1–254 (0 & 255 reserved) |

| Chassis Compatibility | SCXI-1000, SCXI-1000DC, SCXI-1001, and other SCXI chassis |

| Max RS-232 Cable Length | ~100 ft typical (depends on cable capacitance and environment) |

| Backplane | Uses standard SCXI backplane control signals (no user I/O) |

| Function | Remote/control communications module (no analog/digital I/O) |

| Dimensions | Approx. 3.0 × 17.2 × 20.3 cm (1.2 × 6.8 × 8.0 in) |

| Software/Drivers | Legacy NI-DAQ / NI-DAQmx support; check OS and driver compatibility |

If your NI SCXI-2400 Remote Communications Module is not performing as expected, you can easily order a professional repair service from SOHO ProLab. Our technicians specialize in National Instruments SCXI systems and provide fast turnaround with full functional testing and communication verification over RS-232 and RS-485 interfaces.

Moreover, if you need temporary access to a legacy SCXI chassis communication module for testing or multi-chassis network evaluation, you can rent the NI SCXI-2400 directly from us. Renting is a convenient way to maintain productivity in your lab or production environment without long-term investment.

Alternatively, if you have a working or surplus NI SCXI-2400 unit that you no longer need, you can sell it to SOHO ProLab. We purchase used National Instruments modules and provide fair market value offers along with prepaid shipping labels for your convenience.

Whether you need repair, rental, or resale services, SOHO ProLab makes it simple to keep your SCXI systems operational, extend the life of legacy setups, and minimize downtime.

Short summary: Engineers value the SCXI-2400 for its robust RS-485 networking, simple DIP-switch configuration, and durable operation in legacy SCXI test rigs; they also caution to verify drivers, termination, and addressing in multi-chassis networks for best results.

Field reliability and purpose. Test and measurement engineers who still maintain SCXI installations often describe the NI SCXI-2400 as “the missing link” that lets them keep proven rigs alive while their host PCs evolve. Because the module focuses solely on communications rather than measurement, it introduces very little complexity. In many labs, the SCXI-2400 has run for years with minimal intervention: set the baud rate, set the HDLC address, connect RS-232 or RS-485, and the chassis responds consistently. That lean scope is precisely why reliability remains high — there are no extra features to break or re-validate after OS upgrades, provided the serial stack and drivers remain supported.

RS-485 advantages in real deployments. Engineers repeatedly highlight the RS-485 option as the biggest practical benefit. While RS-232 is straightforward for direct PC-to-chassis connections, RS-485 excels when the chassis is on a different bench, in a shielded room, or mounted on a test stand dozens of meters away. With differential signaling, noise immunity improves considerably; consequently, facilities with motors, welders, or VFDs report fewer communication dropouts. Furthermore, daisy-chaining multiple chassis with unique HDLC addresses allows a lightweight, deterministic network that many teams find easier to service than Ethernet-based alternatives in the same era.

Configuration that stays configured. The DIP-switch scheme earns positive feedback because it is both visible and auditable. Instead of hunting through layered software profiles, technicians can physically read the baud and address settings on the front panel. This matters during shift handoffs or after instrument swaps: a glance confirms that address “12 at 57.6 kbps” is still what the procedure expects. Moreover, version control for test recipes becomes simpler when addressing is fixed at the hardware layer and only the host script references those constants.

Integration in legacy workflows. The SCXI-2400 fits into a pattern that many aerospace, automotive, and academic labs still follow: legacy SCXI I/O modules (for strain, bridge, thermocouples, or analog outputs) doing the heavy lifting, with the communications module acting as the stable handshaking point. Engineers who migrated host PCs from Windows XP or 7 to later versions mention that serial comms themselves are typically fine, but the gating factor is the driver package (NI-DAQ or NI-DAQmx) and application APIs. Teams that planned the driver path early — validating on cloned images or VMs — report smooth transitions. Those who deferred this step often faced schedule risk, not because of the SCXI-2400 hardware, but because of OS policy changes and IT imaging cycles.

What to watch for in multi-chassis networks. Practitioners stress several recurring best practices. First, treat RS-485 like the balanced bus that it is: use twisted pair, respect the bus topology, and add proper 120-ohm terminations at the ends. Second, keep stubs short to avoid reflections. Third, ground referencing must be deliberate; floating segments can invite intermittent behavior that looks like “random” packet loss. Fourth, give each SCXI-2400 a unique HDLC address and document it on the chassis faceplate. When these fundamentals are followed, engineers report very stable communications even in electrically noisy environments.

Throughput expectations and latency. Because typical baud rates top out at 57.6 kbps, teams align expectations accordingly. In closed-loop control use cases, the SCXI-2400 is usually part of a supervisory layer rather than a hard real-time loop. Engineers often cache critical setpoints locally in the SCXI modules or rely on deterministic timing at the measurement layer, while the host issues configuration and monitoring commands over serial. This division keeps latency from becoming a bottleneck and reflects the design era’s philosophy: use the serial link for orchestration, not for streaming high-bandwidth data.

Comparison with modern alternatives. Some reviewers compare the SCXI-2400 to USB or Ethernet DAQ controllers, noting the latter can be easier to integrate with contemporary laptops (no serial ports, IT policies, or driver friction). Nevertheless, when the goal is to extend the life of existing SCXI stacks without re-wiring racks or re-qualifying measurement channels, the SCXI-2400 remains compelling. Engineers value the low change-management footprint: you keep the modules and backplane exactly as they are, swap or add a communications module, and continue executing validated procedures with minimal retraining.

Maintenance and troubleshooting notes. In long-running test cells, communication issues generally trace back to cabling or environmental changes rather than the module itself. Reviewers recommend logging link errors, keeping spare RS-232/RS-485 adapters, and labeling DIP settings per asset. For field units, conformal-coated cables and strain relief on screw terminals reduce downtime. If an intermittent fault appears after equipment rearrangement, many engineers immediately check termination resistors and shield bonding before diving into software.

Driver and OS compatibility. The SCXI platform is now considered legacy, so engineers strongly advise confirming driver versions well before a plant-wide OS refresh. In regulated industries, this validation step is included in the change control plan; in academic settings, it is often a lab wiki page with the known-good driver/OS matrix and download links. Teams that keep a small stock of older, supported serial PCIe cards or USB-to-RS-232/485 adapters report fewer surprises when they move host machines.

Cost and lifecycle considerations. From a budget standpoint, reviewers regard the SCXI-2400 as a low-cost extender of system life. Instead of undertaking a wholesale migration to a new DAQ platform (which would require mechanical rework, harness changes, and software rewrites), teams add or maintain a communications module to bridge to newer PCs. As a result, capital expenditures are deferred, and schedules stay predictable. For organizations with validated fixtures — especially those that support trained operators and documented calibration flows — that continuity is invaluable.

Bottom line from engineers. The consensus is pragmatic: the NI SCXI-2400 does a narrow job and does it well. If you need a robust serial bridge to keep SCXI test assets productive, it’s a dependable choice. If your requirements have shifted toward high-bandwidth streaming, plug-and-play USB/Ethernet, or cloud-connected telemetry, then a newer DAQ architecture will be more convenient. However, until that migration happens, the SCXI-2400 remains a trustworthy workhorse that preserves validated workflows with minimal disruption.

Related Products

Related products

-

Rated 0 out of 5

SCXI-1130

-

Rated 0 out of 5

SCXI-1104D

-

Rated 0 out of 5

SCXI-1102C